G-1 UAV Mk.2

After the promising failure of the Mk.1 version, the Mk.2 will take advantage of the following improvements:

-

Wing dihedral, for increased latero-directional stability;

-

Twist of the wing sections for enhanced low-speed control;

-

NACA 4412 instead of the NACA 23015 previously used in Mk.1 for the main wing;

-

New wing structure;

-

Many CNC-cut parts, and extensive fuselage redesign to save weight.

Wing dihedral and linear twist of the wing sections:

Following the accident that occurred to the Mk.1 version due to the loss of control in the initial phase of flight, it is necessary to significantly improve the authority of the ailerons and the behavior at low speed. In fact, the Mk.1 version had two critical points underestimated during the design and construction phase:

-

The quality of the airflow both on the top and on the bottom of the wing due to the balsa spar caps applied on the surface of the polystyrene core, forcing the boundary layer transition to turbulent in a too rough way at the very beginning of the chord and reducing the authority of the ailerons for small deflections;

-

No airfoil twist between the root and the tip of the semi-wings, with the risk that a possible stall may spread violently over the whole span of the wing, also affecting the ailerons making them ineffective.

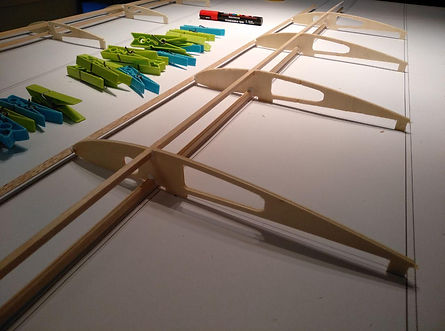

New wing structure

This new structure is made with the concept of placing material only where needed.

Wingbox starts from the leading edge until 1/3 chord and is responsible to resist against wing torsion and bending. It's made by two balsa panels, 1mm thick and a 4mm thick webb closing the section. Bending moment is kept under control also by means of the two stringers located at 1/3 of the chord. The leading edge stringer is used to glue together the upper and lower panels of the wingbox.

Closing the wingbox is very important to ensure the torsional stiffness of the wing since open sections are not supposed to.

As before, the entire wing can be divided in four parts for a simpler transport. Each part is then joined by means of an aluminum tube linking two ribs per wing, aligned with a reference pin and kept in place by a set of very strong magnets.

The linear twist is enforced by two special brackets per rib. Each rib has two brackets located in its lower half to allow an easy construction of the wing section with precise local incidence. Those brackets will be removed once the wingbox is closed.

CNC-cut parts and extensive fuselage redesign

Machining every piece with the appropriate tools ensures better quality of the final product. In this case, airfoils are repeated in each wing section with absolute precision (less than 0.1mm) ensuring fast and precise building of the airframe. I'm helping myself in placing the components in the right place by sticking them with a bit of hot glue to a sheet where I've printed the entire design in 1:1 scale.

.jpg)

Technical data

-

Weight:

-

Maximum take-off mass (MTOM): 3.50 kg

-

Zero payload, full "fuel" take-off mass: 3.00 kg

-

Maximum payload mass: 0.5 kg in the 80x80x150 mm payload vane

-

-

Wing data:

-

Wingspan: 4.0 m

-

Dihedral angle: 4°

-

Root to tip twist: 3°

-

Taper ratio: 0.5

-

-

Performance (ISA conditions)

-

Loiter airspeed: 8 m/s

-

Maximum endurance @ loiter airspeed with 3S LiPo, 4000mAh: 52 min

-

Maximum endurance @ loiter airspeed with 4S LiPo, 6000mAh: too boring to be tested

-

-

Hardware:

-

Battery:

-

Li-Po 3S, 4000 mAh (with 220 g ballast added)

-

Li-Po 4S, 6000 mAh

-

-

ESC: 30A

-

Motor: 320 kV

-

Propeller: folding, carbon fiber

-

Cutting the horizontal stabilizer

Assembling the G-1 UAV mk2

Post flight...

Cutting the horizontal stabilizer